Our Expertise

There are now many promotional merchandise printing processes that are part of the branding process.

Advances in digital printing have enabled short run printing that would not have been cost-effective 10 years ago. These have revolutionised the promotional merchandise sector.

There is also large consumer focus towards more environmentally friendly eco alternatives to traditional products.

Where once plastics dominated the promotional merchandise landscape these have quickly been replaced by bio plastics and other naturally derived materials.

At Keylogo we are constantly expanding our range of eco-friendly products as we work with new suppliers to bring you the best choice of promotional products on the market.

We keep up to date on the latest trends to help your business stay ahead of your competitors when it comes to promotional merchandise. At Keylogo we bring over 20 years of expertise to the table and specialise in the following printing techniques:

A popular printing technique that is incredibly accurate and precise, screen printing has been around for hundreds of years and is commonly used for branding of clothing, plastics, and ceramics. The process involves forcing ink through a mesh which is stretched tightly over a frame which is called a screen, hence the name. Screen printing can be used to print a single colour at a time making it best suited for items that only require a few colours to be used.

|

|

Perhaps one of the oldest methods of personalisation. Embroidery is predominantly used to personalise clothing items such as workwear, uniforms, t-shirts, jumpers and other branded clothing. Using needle and thread multi-colour embroidered designs are possible and are completed using industrial sewing machines that are highly accurate. Colours are matched as closely as possible but will not be a perfect Pantone match as embroidery is limited by the colour of thread.

|

|

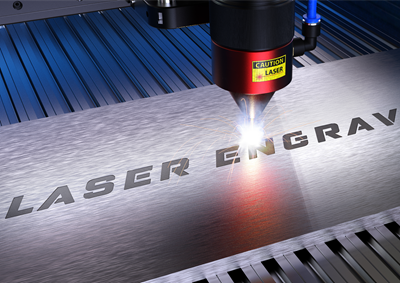

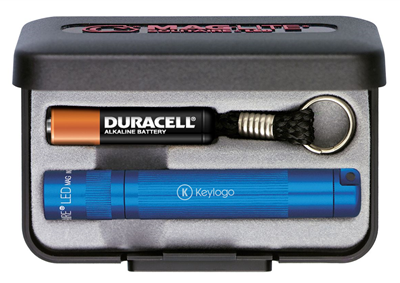

A highly accurate and permanent form of imprinting, laser engraving uses a computer-controlled laser to engrave designs into solid materials. Laser engraving can be used on materials such as wood as well as plastics, metals, stone, and glass. This is one of the most precise forms of decoration and creates a unique effect with your design imprinted into your chosen material.

|

|

In recent years digital printing has transformed the printing industry and has made lower print run productions cost-effective. There are a number of different digital printing techniques with some of the most common being direct digital printing, digital transfer, epoxy doming and dye sublimation. Digital printing allows full colour printing of objects in an almost unlimited range of colours and shades.

|

|

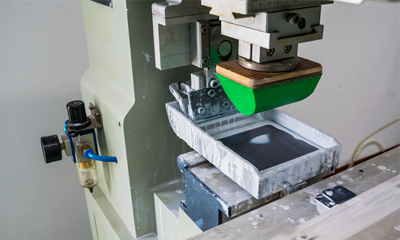

A great choice for products with an even surface, pad printing uses a pad made from silicone or rubber which is coated in ink before being pressed onto the chosen promotional product. It is the perfect option for products such as pens, folders, cups, phone cases and much more. Because of the flexibility of the ink pad printing can be carried out on a huge range of surfaces and products.

|

|

Embossing creates a 3D effect with the logo raised against the background material while debossing is where the logo is sunken into the background material. Both of these processes create a very tactile effect that looks great on a number of materials from plastics to natural materials like leather. The effect is also subtle with a unique change in tone caused by the embossing or debossing.

|

|